UK Manufacturing

The Making of our Turning Tools

The new ProComfort trilobe design handles have been developed over three years with ergonomics experts from Sheffield Hallam University and are designed to offer a comfortable, natural and intuitive fit in the hand. This means that significantly less gripping power is needed when in use, which reduces fatigue, increases control and makes turning significantly more enjoyable and easier. These tools have been tested by many professional international woodturners and keen hobbyists, to ensure the best profile has been chosen to deliver the best results.

Spindle and Bowl Gouges

The flutes are machined on a modern 3-axis CNC machine and in the case of the bowl gouge, using bespoke tooling to create an improved flute profile.

Spindle Roughing Gouge

The roughing gouge starts life as a CNC laser cut blank profile which is then heated to around 1000°C and forged into the final profile using bespoke form tooling.

-

Flat Tools: Scrapers, Parting Tools and Skew Chisels

These are produced as CNC laser-cut blanks. The blanks undergo some surface processing prior to heat treatment to remove marks created by the laser cutting process.

-

Carbide-Tipped Tools

The shafts are CNC-machined to form the tangs and tips, then the tips are milled to accommodate the different shapes of the carbide cutters.

Heat Treatment

All traditional turning tools undergo salt bath heat treatment and are then tempered back to a hardness of between 60 and 64 HRC (Rockwell C scale). The tang/top of the tool is not hardened, so that it remains ductile and not brittle. This reduces the risk of failure of the tool in use.

Surface Finishing

All our turning tools undergo various levels of surface treatment including deburring and polishing, giving them a premium-quality finish. These processes also remove the scale created during heat treatment.

Spindle Roughing Gouge, Spindle Gouge and Bowl Gouge

The heat-treated tool is sand blasted to remove scale which builds up on the surface of the steel as part of the process of heat treatment. The outer surface of the tool then goes through a four-stage polishing process to remove any residual scale and/or surface pitting that may be present.

Similarly, the flute of the tool is cleaned with a formed abrasive wheel and then polished with a fine abrasive compound to remove any marks left by the previous process, creating a fully polished flute.

Scrapers, Parting Tools, Skew Chisels and Carbide-Tipped Tools

They are then laser-marked to allow easy identification and in the case of the carbide-tipped tools, to also show the safe overhang area of the shaft over the tool rest.

-

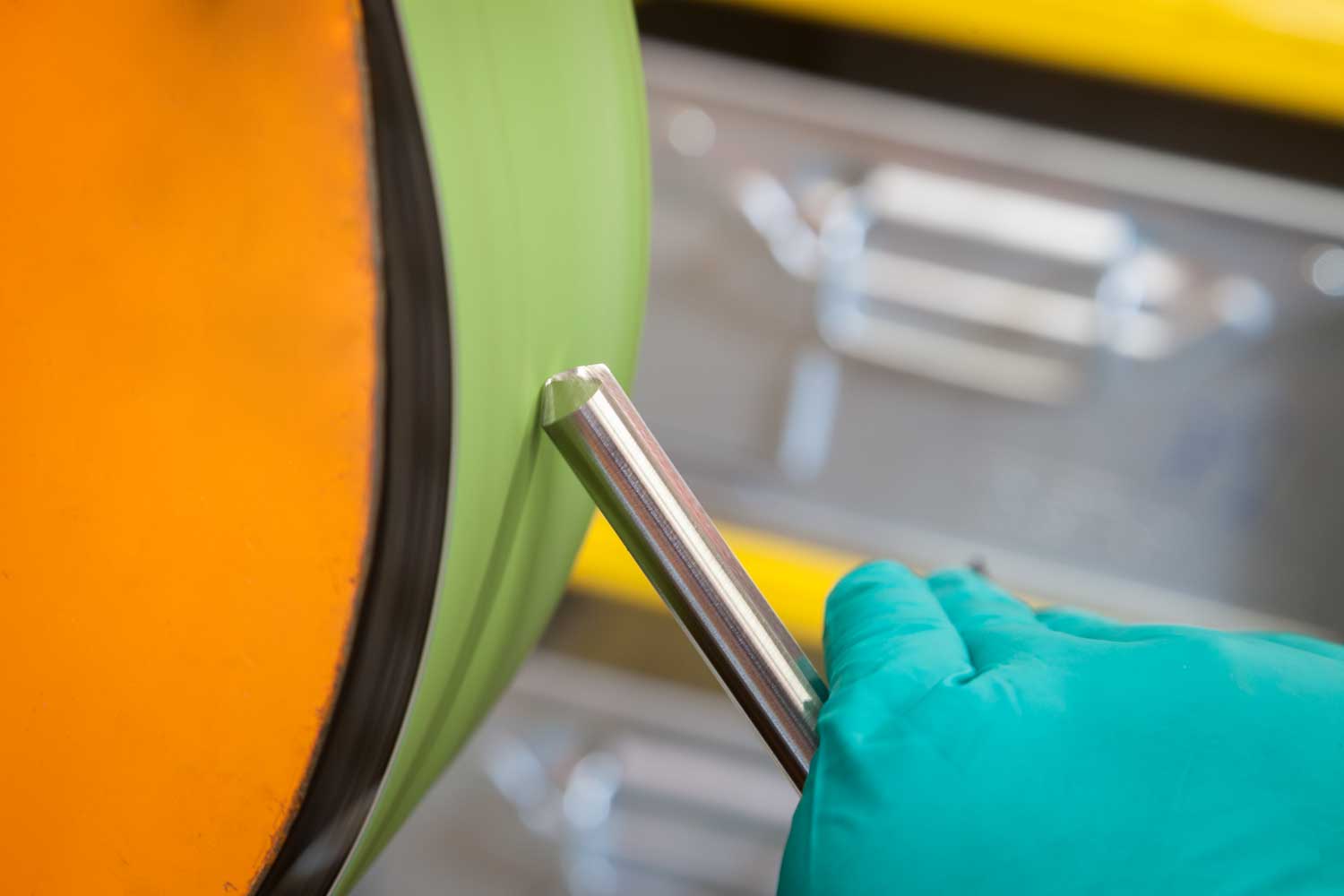

Grinding of the Bevel

All traditional tools have bevels and cutting edges finished by hand. Ceramic abrasives are used in order to prevent the edge of the tool from overheating whilst being ground.

-

Handles

Our traditionally shaped handles are turned from high-quality beech wood using CNC lathes and finished carefully by hand. The ProComfort handles are specially made using a custom process in order to achieve the trilobe profile, which involves CNC machinery and custom jigs and fixtures.

Final Assembly